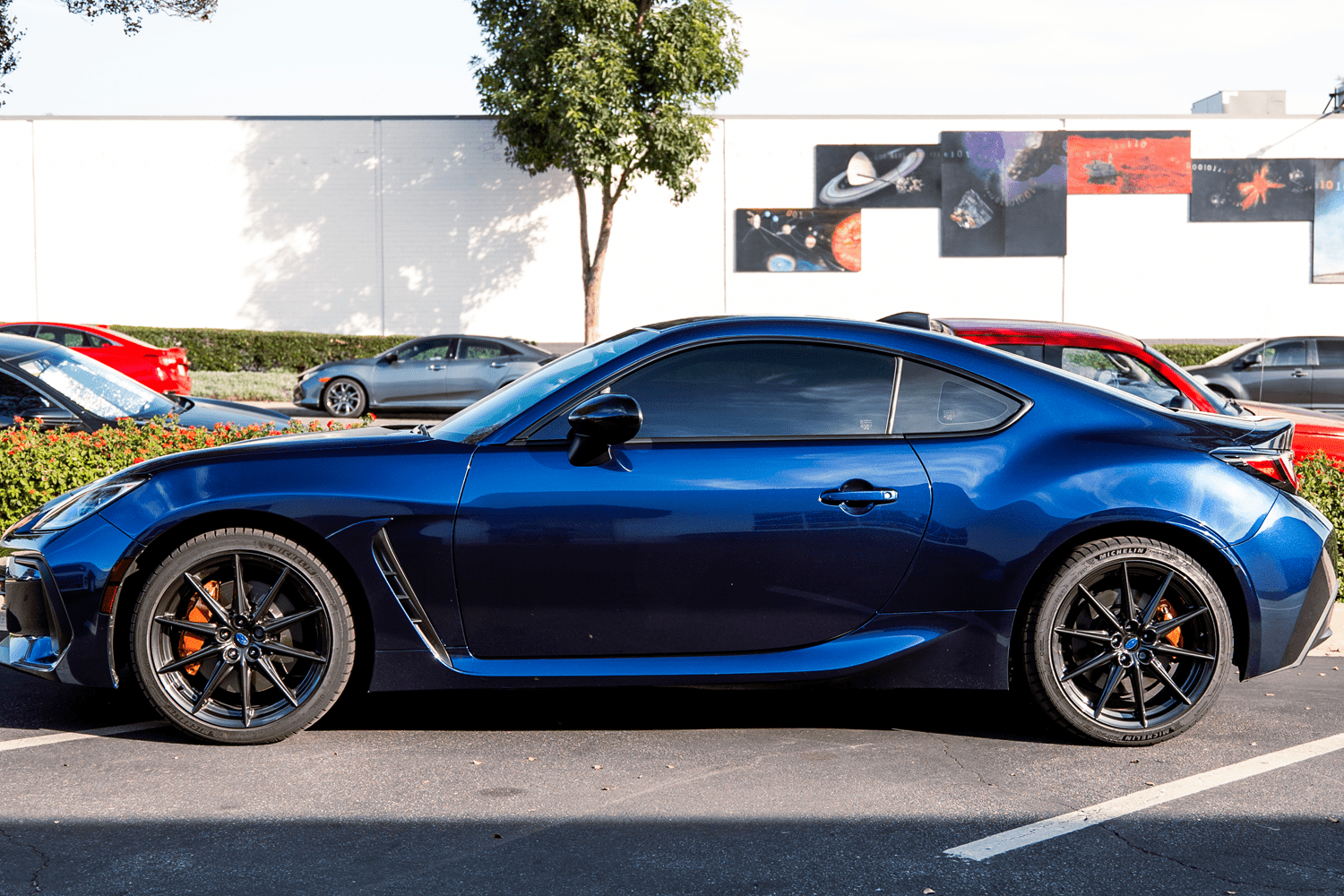

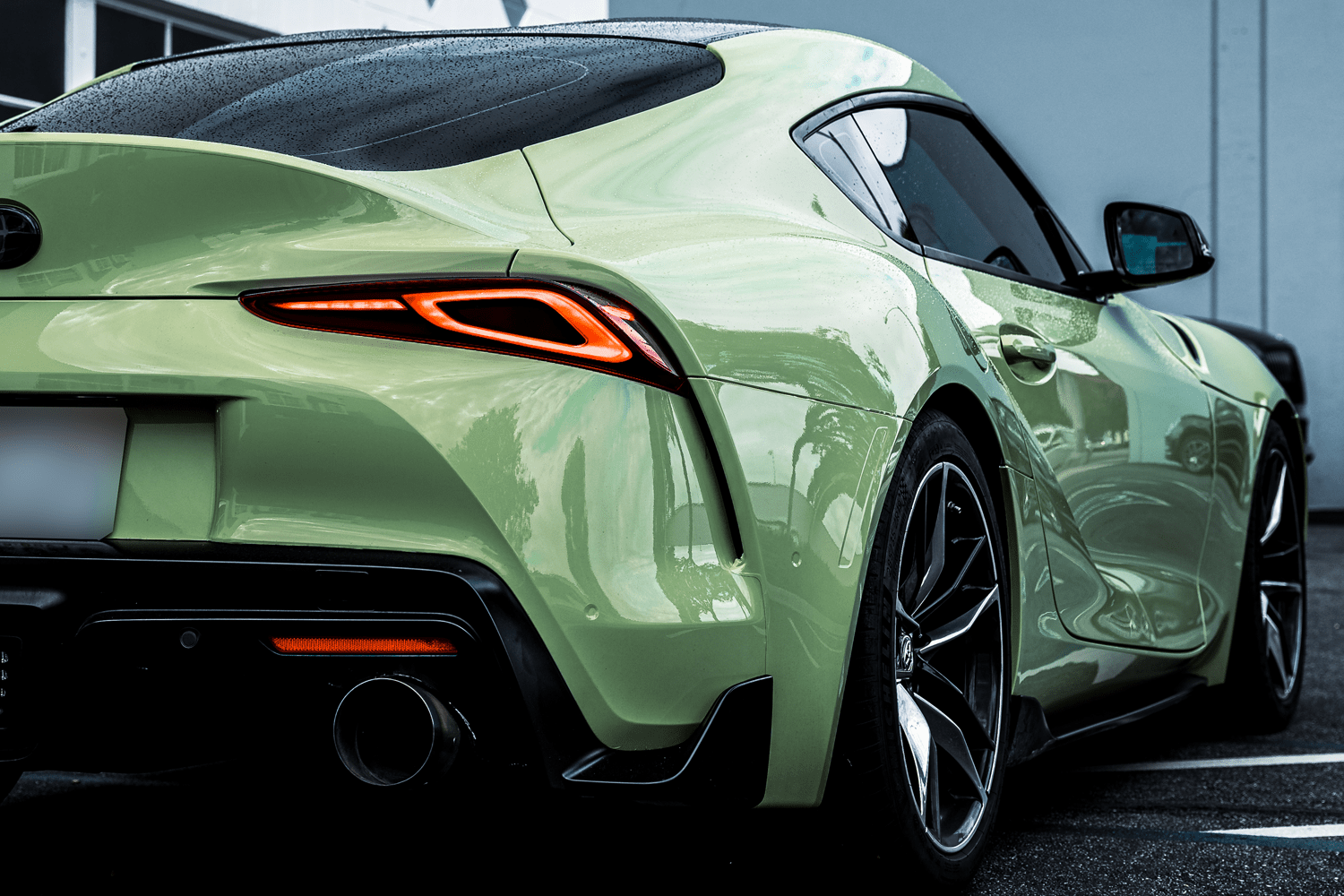

Peak PPF: Precision Color, Personal Service, Protection Without Compromise

Welcome to the Peak of Paint Protection

If you spend your days around super-sedans, vintage exotics, or freshly delivered EVs, you already know that automotive paint lives a tough life. High-velocity gravel, acidic bug splatter, industrial fallout, and careless door dings all conspire to dull a flawless finish. Paint protection film (PPF) was invented to solve that problem. But like every great idea, execution is everything.

Today, we're proud to introduce Peak PPF, the your premier paint-protection brand build from the ground up for dealers who serve discerning, performance-obsessed drivers. We combine truly custom manufacturing, a vibrant 97-color launch palette, and a relationship-first distribution model that helps you win lifetime clients instead of one-off installs. Our promise is simple: protection without compromise - for the car, for the installer, and for the owner.

Why PPF Still Matters

Clear-coat chemistry has improved, but even advanced finishes are only microns thick. Impacts, UV exposure, and contamination begin degrading paint from the moment a car leaves the showroom. Ceramic coatings add gloss and hydrophobics yet lack meaningful impact resistance. Vinyl wraps provide color but are not engineered to absorb repeated hits. PPF remains the only solution that blends optical clarity, self-healing properties, and sacrificial thickness into one layer.

Traditional suppliers solved the protection problem, but the market evolved in three critical ways:

- Personalization: Owners want color and texture options, not just clear film.

- Speed: Installers need quick, predictable lead times to win projects.

- Margin: Shops must protect profitability against online price shopping.

Peak PPF exists precisely where those three needs intersect.

The Peak PPF Difference

Instead of pulling from a warehouse of pre-made stock, each Peak PPF roll is built after a purchase is received. That custom-manufacturing model unlocks advantages that off-the-shelf cannot match.

- Factory-Fresh Quality: Film arrives at your shop days after extrusion, so the adhesive has not aged under fluorescent lighting and the top-coat has not absorbed humidity. Straight-from-the-line product means easier stretching, quicker tack, and a finish that stays crystal clear for years.

- Exact-Fit Sizing: Order any width from narrow accent strips to full-body panels. Less trimming equals faster installs and fewer off-cuts headed to landfills.

- Tailored Chemistry: Need extra-thick film for a track-dedicated splitter? Prefer a hydrophobic top-coat for daily drivers that live outdoors? Peak engineers dial in resin blend, thickness, and surface chemistry to match the mission.

Color Without Compromise

Peak PPF launches with a spectrum of ninety-seven verified shades across gloss, satin, front, and pearl finishes. Because pigment is mixed at the moment of manufacture, shade consistency is controlled to a Delta-E of less than one, meaning the human eye cannot detect the difference between two production runs.

Dealers may also request private colors. Secure a hue that mirrors a heritage pain code or invent something entirely new - either way, that color can remain exclusive to your territory for an agreed-upon launch window. Customers win bragging rights, and your shop becomes the only destination in town for that look.

Installer-First Engineering

Experienced wrappers often describe film as either cooperative or combative. Peak PPF film is designed to cooperate.

- Low-Memory Core: The polyurethane stretches evenly and then relaxes flat, eliminating the orange-peel texture that can plague high-contour panels.

- Controlled Tack Adhesive: Initial bond is gentle enough to reposition, yet strong enough to lock out air channels with a single squeegee pass. Edges stay put rather than lifting during post-heat.

- Self-Heating Surface: Fine swirl marks dissipate with mild heat from sunlight or warm water, keeping maintenance simple for owners and warranty claims low for installers.

In blind time-trials on identical front-clip installs, technicians trimmed an average of eighteen percent off their labor hours after switching to Peak PPF. Less fight = more profit.

Sustainability by Design

Made-to-order manufacturing eliminates speculative inventory that might yellow on a rack, then end up in a dumpster. Water-based adhesive carriers minimize volatile organic compounds during curing. Scrap trim from the slitting line is compacted an shipped to polyurethane recyclers where it becomes athletic-surface padding. Even sample swatch chips use recycled cardboard cores instead of virgin plastic. The lifecycle footprint shrinks at every step.

Innovation Roadmap

Peak PPF does not stop at the current product line. Ongoing research focuses on three pillars:

- Lower-Temperature Self-Healing: Ideal for colder climates where sun exposure is limited for months at a time.

- Adaptive Finish Technology: A proprietary polymer networks that shifts from gloss to satin under specific light wavelengths, giving owners the ability to change aesthetics seasonally without a re-wrap.

- Bio-Based Cores: Engineering teams are testing TPU derived from non-food corn ethanol, targeting a thirty percent reduction in carbon footprint compared with petroleum-based film.

What This Means for Car Owners

- Invisible Armor: Transparent film maintains factory lines while absorbing the abuse of everyday driving.

-

Personal Expression: Color options transform protection in a design statement.

- Future Value: A flawless paint job boosts resale appeal and reduces reconditioning costs.

- Peace of Mind: Self-healing properties keep the finish pristine without endless polish sessions.

Drivers gain confidence to log miles without worrying about unpredictable chips or scratches.

What This Means for Installers

- Higher Ticket Averages: Color and custom specs justify premium pricing.

- Faster Throughput: Installer-friendly behavior translates to more vehicles wrapped each week.

- Easier Sales Conversions: Exclusive products remove the need to match online discount listings.

- Stronger Brand Identity: Marketing assets and content partnerships elevate local visibility.

The collective result is a healthier bottom line and a brand reputation anchored in craftsmanship.

Why Peak PPF is the Future

Automotive culture is experiencing a renaissance of personalization. Electric powertrains, digital cockpits, and direct-to-consumer sales channels are reshaping how drivers relate to their vehicles. Protection products must evolve in tandem, delivering not just durability but also identity, sustainability, and dealership-grade support.

Peak PPF embraces that challenge through custom manufacturing, color freedom, and a partnership model that treats installers as co-creators. The brand is built for entrepreneurs who refuse to accept mass-production mediocrity and for owners who view their cars as rolling pieces of art.

Protection, expression, innovation. this is the future, and Peak PPF sits at the summit.

Ready to Elevate Your Installs?

Ready to elevate your installs, captivate clients, and secure your share of tomorrow's market? Reach out today to experience the difference of film fashioned precisely for you. Together, we will keep every curve, crease, and contour looking perfect for years to come, one custom-tailored roll at a time.